Services

We offer a diverse range of services to meet

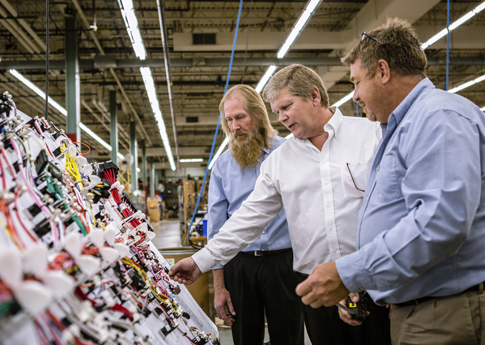

ENGINEERING SUPPORT

We have a dedicated team of electrical and mechanical engineers, each with an average of 31 years of experience, that work closely with our customers. Engineering personnel, in conjunction with production staff, will collaborate with your design team to validate supplied documentation and develop manufacturing processes as required. Should any issues be identified before or during production, we will communicate directly with you and your technical staff to ensure the project will be completed successfully. While our customer retains all design authority, our on-site engineering team can aid with prototype development and consult on design related issues.

SALES AND ESTIMATING

Our expert team of account representatives and estimators work diligently to complete your quotes in a timely fashion. Our core sales and estimating personnel have electrical assembly manufacturing backgrounds, allowing for proactive comprehensive review of the work being quoted. This process includes identifying potential problem areas to eliminate delays during production.

QUALITY

Mercury has a devoted quality team that will inspect your product both during the build process and at completion. We build and test according to IPC-A-620 cable and wire harness standards and have a certified IPC-A-620 trainer on staff. We are also ISO 9001/AS9100 certified. Our quality staff is trained to use automatic testing equipment including continuity, high pot, and Meg Ohm. When required, we will provide detailed inspection documentation and reporting on individual assemblies. As an additional quality measure, our team will design and build dedicated custom test fixtures to validate the accuracy of your assembly.

MATERIAL PLANNING CAPABILITIES

We will work with customer provided forecasts for maintaining sufficient raw material levels as well as management of long lead items. Inventory of these materials can be secured at our facility to reduce customer lead times. We can also offer managed inventory of customer supplied materials.

VENDOR MANAGED INVENTORY

We have the ability to set up and maintain a Kanban system of single bin replenishment, two and three bin rotation systems, or MIN/MAX programs. The details of our managed inventory can be customized to your requirements.

MANUFACTURING PROCESSES AND TECHNIQUES INCLUDING:

- CUT, STRIP, AND TERMINATE

- SPLICING

- MECHANICAL CRIMP

- SOLDER SPLICE

- ULTRASONIC WELDING

- SOLDERING

- CRIMPING

- POTTING AND ENCAPSULATION

- WIRE MARKING

- INLINE INKJET PRINTING

- SHRINK TUBING

- WRAPAROUND LAMINATE MARKERS

- OVER-BRAIDING

- EMI SHIELDING AND WATERTIGHT HARNESS ASSEMBLY

- AUTOMATIC LABELING

- BAR CODING

- ESD PROCESSING

- SPECIAL PACKAGING

- AUTO BAGGING

- PLUS THE CAPABILITY TO HANDLE MANY OTHER OPTIONS BASED ON YOUR SPECIFIC NEEDS!